Hybrid Polymers – More Sustainable Polymer Solutions for I&I Cleaning

Recent cleaning product launches in the Industrial and institutional (I&I) cleaning segment indicate this segment is trending greener. Formulators, therefore, may be looking for ingredient alternatives while maintaining or improving overall product cleaning performance. One way to make a cleaning product greener is to select eco-friendly biodegradable ingredients such as hybrid polymers that work as soil anti-redeposition agents.

How polymers work in laundry and automatic dishwashing cleaning

Dispersancy of soil can play an important a role in removing deposits from textiles in laundry and dishes in automatic dishwashing (ADW). As the cleaning cycle begins, surfactants and other ingredients generally do the bulk of the work to remove stains, but then as the cleaning cycle progresses the soil and stains that are removed can redeposit back onto the surface making linens look dingy and dishes less than sparkling clean. Polymers also minimize deposition of calcium carbonate scale delivering anti-encrustation in laundry and anti-filming in ADW. Further, any cleaning ingredients used are discarded along with the wash water and can end up back in the ground making for a non-green footprint.

Polymers are commonly used to disperse and suspend soils and minimize scale deposition, then are discarded in the rinse cycle. Unfortunately, commonly used polymers are synthetic and are not biodegradable. To make polymers more eco-friendly, hybrid polymers were introduced into the market. Hybrid polymers are polysaccharides used in combination with synthetic monomers to provide dispersancy and prevent scale formation in detergent applications. These polymers are particularly effective at anti-redeposition and anti-encrustation in laundry and minimize filming and spotting in zero phosphate automatic dishwash formulations. They perform similarly to synthetic polymers. The difference is that hybrid polymers provide biodegradation, renewable carbon index (RCI), and improve raw material sustainability.

Importance in a greening market

With the greening of markets where the U.S. Environmental Protection Agency’s (EPA) Safer Choice Program, European Union (EU) Ecolabel, and Nordic Environmental Label are becoming increasingly important, the need for polymers from renewable sources are also important. Hybrid polymer technology provides the following benefits:

- Favorable environmental impact

- High cleaning performance

- Less dependence on synthetic monomers

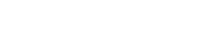

- Improved carbon footprint v. synthetic polymers (see Figure 1)

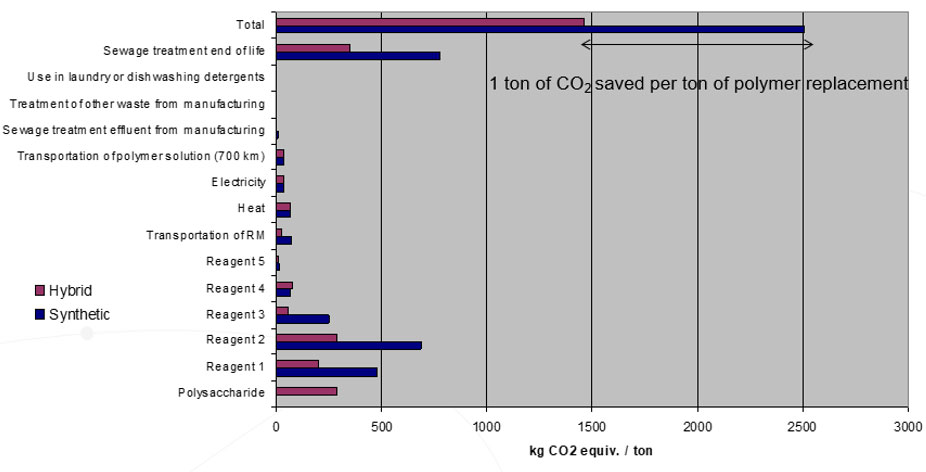

- Enhanced biodegradability and RCI (see Figure 2)

Figure 1: Hybrid polymers – carbon footprint

Figure 2: Renewable carbon index

Performance

Performance is also important since it cannot be sacrificed for improved “greenness.” Hybrid polymers can provide anti-filming (scale control) and dispersancy performance on par with synthetic polymers as shown in Figures 4, 5, and 6. This is mainly due to its unique mechanism of scale control which is detailed below.

Filming

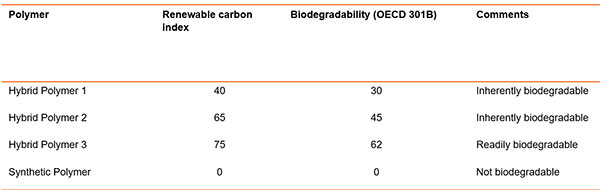

Encrustation in laundry and film formation in ADW is due to carbonate scale depositing on surfaces. Carbonate scale formation increases with increasing hardness, increasing levels of sodium carbonate, high temperature, high pH, and lower total electrolyte concentrations in the cleaning environment. Polymers control scale deposition by threshold inhibition as well as crystal growth modification and dispersancy (Figure 3).

Figure 3: Mechanism of anti-scaling

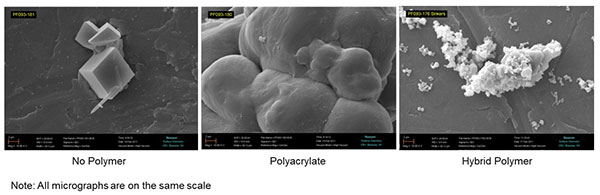

The hybrid polymer architecture is such that the polymer significantly changes both the size and morphology of the crystal scale. These changes limit scale deposits onto surfaces (fabrics in laundry or dishes/glasses in ADW) and increases scale dispersion to allow for removal during the rinse phase.

This effect is demonstrated in comparison to a traditional polymer in Figure 4.

Figure 4: Calcium Carbonate Crystal Growth Comparison

With no polymer present, typical hard water ions form stable, cube-shaped crystals. This allows for the crystals to layer on top of one another in a very stable and ordered structure making it difficult to prevent deposition and build up. A typical polymer may modify crystal morphology, but to a significantly less degree, and may lead to deposition on surfaces as the number of wash cycles increase.

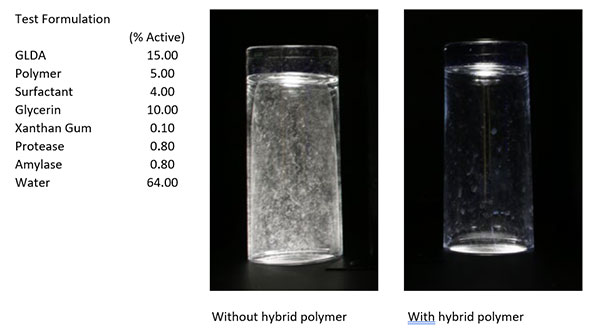

In the case of ADW, scaling can be prevented using a hybrid polymer as shown in Figure 5.

Figure 5: Scaling difference in ADW with v. without hybrid polymer

The benefit of using a hybrid polymer is anti-filming, anti-spotting, dispersancy and soil suspension.

Hard surface cleaning (HSC) performance

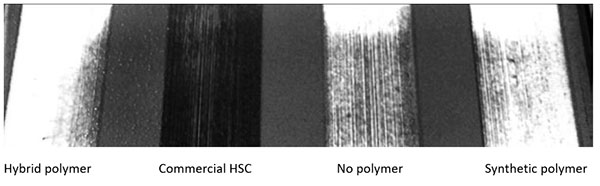

Hybrid polymers can enhance surfactant cleaning performance in HSC by dispersing inorganic soils. Figure 6 shows the hybrid polymer’s performance when added to a hard surface cleaner against a commercially available HSC, no polymer, and a synthetic polymer.

Figure 6: Contribution of Hybrid polymer on all purpose cleaning evaluation of IKW Soil on vinyl composite tile

Summary

Hybrid polymers can be effective at replacing synthetic polymers in cleaning applications such as ADW, laundry, and HSC. They work by dispersing soils and minimizing deposition of carbonate scale. In keeping with sustainable trends, they can be more biobased and are more biodegradable depending upon their composition.

For more information, please reach out to Nouryon at nouryon.com/markets/cleaning

All information concerning Nouryon ‘s products and/or all suggestions for handling and use contained herein (including formulation and toxicity information) are offered in good faith and are believed to be reliable. However, Nouryon makes no warranty express or implied (i) as to the accuracy or sufficiency of such information and/or suggestions, (ii) as to any product’s merchantability or fitness for a particular use or (iii) that any suggested use (including use in any formulation) will not infringe any patent. Nothing contained herein shall be construed as granting or extending any license under any patent. The user must determine for itself by preliminary tests or otherwise the suitability of any product and of any information contained herein (including but not limited to formulation and toxicity information) for the user’s purpose. The safety of any formulations described herein has not been established. The suitability and safety of a formulation should be confirmed in all respects by the user prior to use. The information contained herein supersedes all previously issued bulletins on the subject matter covered.